Why Dantherm uses EPS instead of EPP as insulation in ventilation units

- Home

- Insights

- Ventilation insights

- Why Dantherm uses EPS instead of EPP as insulation in ventilation units

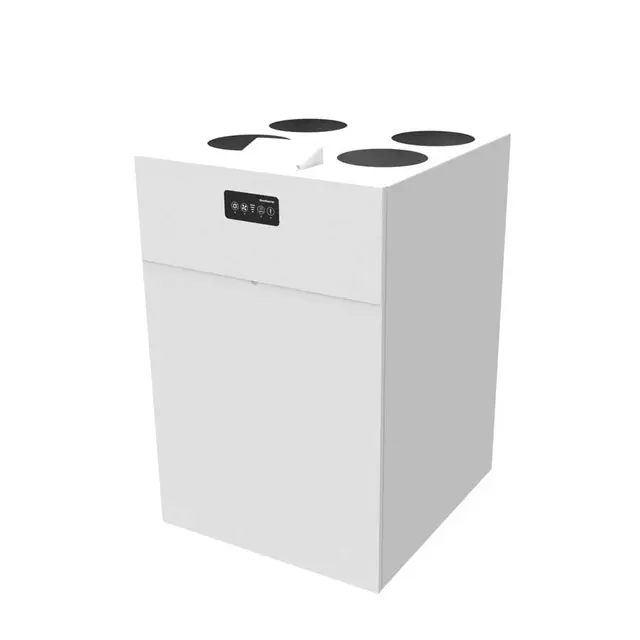

Ventilation units need to be well-insulated, compact, and robust. The choice of material therefore plays a crucial role. For insulation, either expanded polypropylene (EPP) or expanded polystyrene (EPS) is used. At Dantherm, we use EPS in combination with a steel casing.

The use of EPS with a steel casing is partly due to certain technical properties of the material, and partly because Dantherm has extensive experience with EPS and benefits from a fine-tuned production setup and a strong value chain from raw material to finished product.

Dantherm was one of the first manufacturers to use expanded foam as insulation back in 2008. Among other things, Dantherm has a close and unique collaboration with a manufacturer that specialises in developing and producing technically complex components in both EPS and EPP.

Dantherm is not tied to any specific technology. This means we always choose the material that delivers the best result based on practical and objective considerations. If we assess that EPP offers greater advantages, we would not hesitate to switch. But until we have better evidence, EPS combined with a steel casing remains the preferred solution.

“We benchmark EPS against EPP every time we develop a new product, and so far, EPS in combination with a steel casing has consistently scored higher.”

Allan Nørgaard Madsen, Engineering Manager Residential Ventilation, Dantherm Group

What is the difference between EPS and EPP?

EPS and EPP are both foam materials commonly used for packaging, insulation, and product protection. Both are synthetic, oil-based polymers, but they differ in physical properties such as density and compressive strength. The material’s durability depends on whether it is used as intended.

Dantherm’s choice to use EPS is rooted in our unique history and experience with the material. We have been able to exploit its fine tolerances to create a design with very few joints. This results in maximum airtightness in the unit without the need for additional sealing.

Additional advantages of choosing EPS:

- EPS offers better insulating performance than EPP due to its lower density. EPS consists of 98% air and 2% material.

- EPS can be moulded in very large pieces (EPP is easier to mould in small pieces).

- EPS has very fine tolerances, allowing for greater design freedom and flexibility during assembly.

- EPS can be glued (EPP is difficult to glue).

- EPS meets the same fire safety standards as EPP.

- EPS requires less energy than EPP during moulding.

- EPS raw material occupies significantly less space than EPP, resulting in minimal CO₂ emissions during transport prior to processing.

- In combination with a steel casing, EPS provides better sound insulation than EPP.

- A ventilation unit with a steel casing appears more robust and hygienic.

For more information about Dantherm’s ventilation units, please contact us here or fill in the form below.

Related products

Featured insights

Denmark’s largest housing renovation project focuses on indoor climate.

Residential ventilation is crucial for the future of buildings globally – find out why here.

Explore the bespoke ventilation system we developed for one of Denmark’s key prestige buildings.

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.