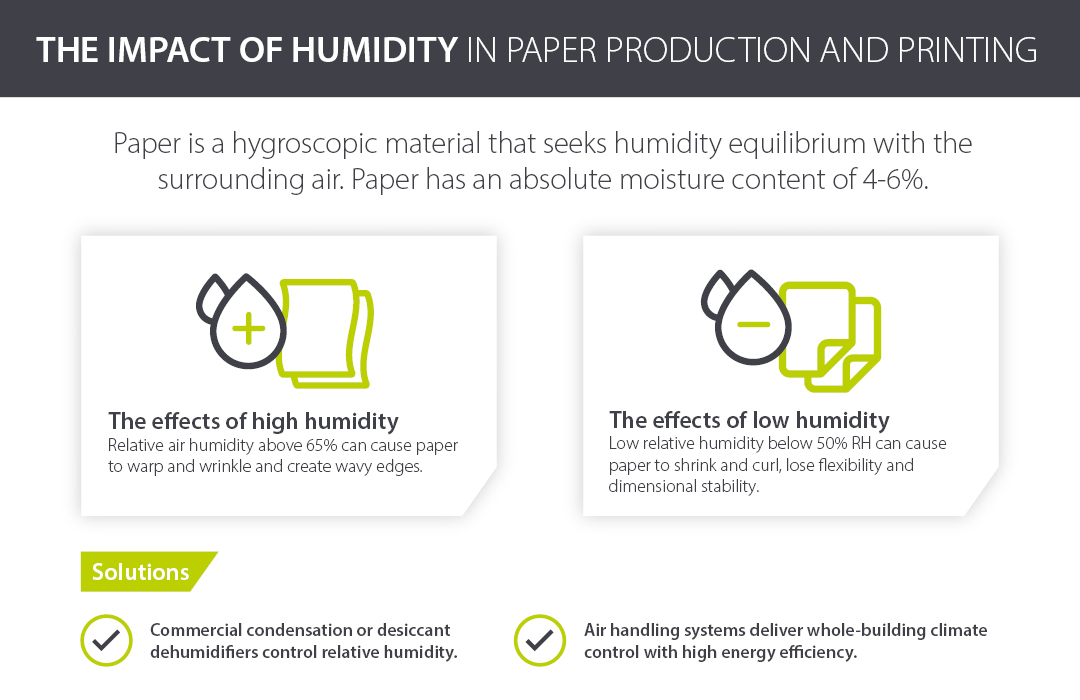

The impact of humidity in paper production and printing

Humidity control is one of the most critical factors in paper production and printing. Paper is a hygroscopic material, which means it naturally absorbs and releases moisture depending on its surrounding environment. This moisture exchange can affect paper dimensions, conductivity, and flatness leading to production issues, quality defects, and costly downtime if not managed properly. Maintaining stable humidity levels ensures paper stays in optimal condition from manufacturing through to the printing stage.

Why paper reacts to humidity

Paper constantly seeks equilibrium with the surrounding air. Under stable conditions – typically between 50-60% relative humidity (RH) and 18-20°C – it neither absorbs nor releases moisture. However, if the air is too dry or too humid, the paper will lose or gain moisture, potentially causing significant changes to its physical properties.

Manufacturers typically produce paper with an absolute moisture content of 4-6%, meaning water accounts for 4-6% of the paper’s total weight.

Maintaining a stable and optimal indoor climate can be challenging in large production facilities, where a constant flow of people and poorly insulated buildings may allow outside air to disrupt the indoor environment.

The effects of low humidity on paper quality

When relative air humidity drops below 50%, paper starts to lose moisture, leading to:

- Shrinkage and curling, reducing dimensional stability and causing problems during slitting and wrapping.

- Loss of flexibility, increasing the risk of fold cracking.

- Static electricity buildup, particularly below 45% RH. This causes sheets to stick together, leading to feeding and jamming problems, poor printing performance, and even safety hazards from electric shocks.

- Invisible damage during slitting. Moisture loss occurs quickly, but visible curling often appears later during sheeting, once the paper is no longer under tension.

Maintaining around 55% RH helps preserve the paper’s moisture content, flexibility, and stability, ensuring smooth production and packing.

The effects of high humidity on paper quality

When relative air humidity exceeds 65%, paper absorbs excess moisture, which can lead to:

- Fibre expansion making paper limp and edges wavy.

- Warping and wrinkling creating difficulties during processing and printing.

- Mould growth, a serious quality issue in stored paper stock.

Temperature and acclimation

Extreme temperatures typically do not damage paper, but temperature swings can cause problems during printing. Best practice is to acclimate paper for at least 24 hours before use and store it in a climate-controlled area to maintain consistent temperature and humidity.

Solutions for humidity control

Dehumidification and air handling

In humid climates or seasons, dehumidifiers can maintain production and storage areas at optimum RH levels. Depending on the application, condensation or desiccant dehumidifiers can be used to keep moisture levels stable and prevent issues like warping or mould.

In dry conditions, introducing humidity is essential to prevent shrinkage, static build-up, and cracking.

Commercial air handling units are large systems capable of delivering highly efficient whole-building climate control. Air handlers draw in outdoor air and clean, heat or cool it, depending on the needs of a certain space. Conditioned air is supplied to where it is needed, and stale air is extracted while heat is recovered. Air handling units maintain humidity and temperature levels, as well as the air quality that is needed to ensure both the well-being of people and product quality.

Balanced humidity is key

Preserving a stable humidity level is essential to keep paper production and printing efficient, consistent, and cost-effective. By controlling RH within the recommended range and acclimating paper before use, manufacturers can prevent curling, jamming, static issues, and quality defects. Climate control is an investment in smoother operations and higher-quality output.

For further information, please contact an office near you or fill in the form below.

Related products

Featured insights

Why unregulated humidity creates big problems for paper

How glass manufacturer ESG cut energy costs by 30% without compromising performance

Purpose-built solutions for industry leaders

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.