Why Controlled Environment Agriculture (CEA) is the future of farming

- Home

- Insights

- Humidity control and drying insights

- Why Controlled Environment Agriculture (CEA) is the future of farming

In agriculture, technology is constantly improving and innovating to reduce manual labour, increase efficiency and improve the quantity and quality of output. If you’re a farmer or you work in the agriculture industry, you will have probably come across the concept of Controlled Environment Agriculture (CEA) already. Combined with existing farming practices, this revolutionary growing method has the potential to change the course of agriculture as we know it.

What is CEA?

CEA is a method of creating fully controlled environments for growing plants. This is sometimes referred to as ‘vertical farming’ or ‘indoor farming’. As the name suggests, these facilities are sealed off from the outside environment. Everything plants need at their various growing stages is provided artificially, including water, temperature, humidity levels, ventilation, light and CO2.

Inside a CEA facility, you’ll see produce underneath LED growing lights with hydroponic (or aquaponic) systems providing water and nutrients. Heaters, ventilators, dehumidifiers, CO2 enrichment, humidifiers and coolers are used to regulate optimum growing climates.

These sheltered, controlled mini-ecosystems mean that plants can be grown all year round. They are safe from outside contamination (including E. coli) and make use of UV lights to remove bacteria.

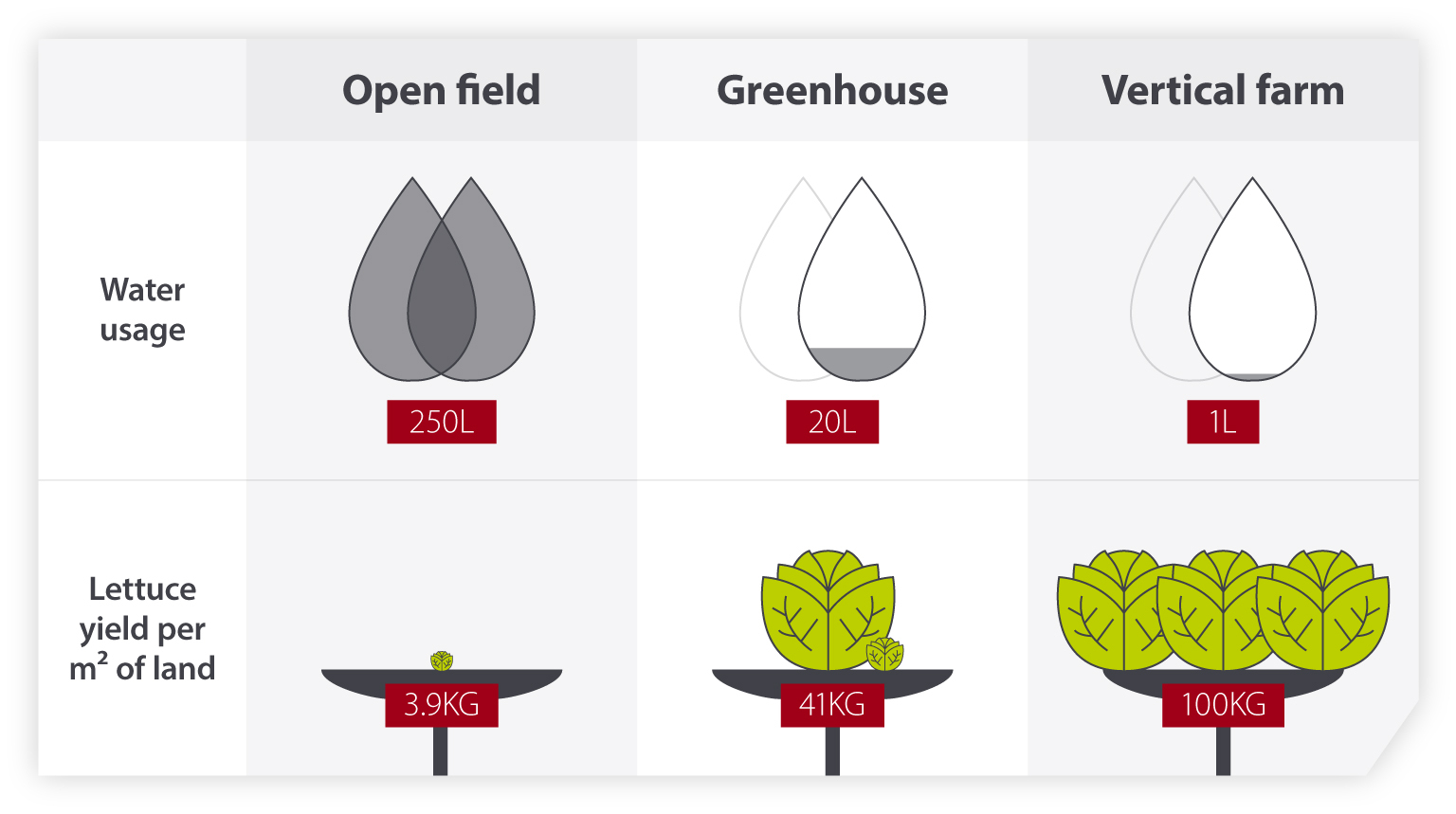

When you can remove the challenges that come with traditional farming, the implications on output, long-term cost savings and environmental impact are enormous. There is significantly less need for heavy machinery, pesticides, herbicides or fertilisers, and you will use significantly less water (CEA allows us to produce crops with 70% to 95% less water than required for normal cultivation).

The infographic below shows the major water savings of CEA (using lettuce growing as an example):

The most obvious saving is in land usage. When crops are stacked vertically inside a purpose-built facility, you can produce the equivalent of around 4-6 acres in a single indoor acre.

Of course, this will vary depending on the crop. If you are growing strawberries, for example, traditional farming would require 30 acres to produce the same amount as one acre of vertical farming space.

In addition, crop yields are also higher in controlled environments as the effects of seasonality are reduced. Every single day is a perfect summer’s day, with a photoperiod long enough to ensure maximum growth potential.

Cons

- Emerging technology

- High initial costs

- High maintenance costs

- Significant energy usage

- Pollination can be difficult

What does CEA look like today?

Despite the benefits sounding like a vision of the distant future, CEA is already proving instrumental for the production of pharmaceutical products. Most notably, cannabis production for medicinal, cosmetics and health supplements. As more countries introduce licences and relax laws, the cannabis industry is set to explode, with Europe’s CBD market estimated to grow over 400% through 2023.

Cannabis is a high-value crop that needs consistent and absolute conditions to produce a yield that meets the standards required. CEA methods are automating this level of control, maximising the practicality and profitability of cannabis growing.

Small scale set-ups

Some farms and farm shops have been able to benefit from small-scale CEA set-ups to diversify their produce. Flowers, herbs and micro-salads are well-suited to CEA layouts as space can be maximised. This has helped reduce their supply chains and offer their customers consistent, high-quality produce that is difficult to source locally.

The main challenge for the adoption of CEA for traditional and regional farmers is obtaining the necessary support and expertise to establish the facility. There are organisations that can offer this support, including the equipment needed to set up a small-scale CEA facility.

“Increasingly it is no longer necessary to buy CEA equipment from a single provider, such as those offering fully-fitted container units or equivalents,” explains Dr William Stiles of Vertikit, an organisation bringing the best technologies together into a one-stop CEA and vertical farming shop to support the industry’s development.

“More and more manufacturers are specialising in the components needed to create a controlled environment, such as the lighting or environmental control equipment, rather than trying to sell 'turn-key' solutions.”

“This gives growers the ability to select the right apparatus for their own specific needs, and offers the potential to change how this marketplace will develop. The provision of full solution systems has been an issue for the emerging industry, as the capital investment required for a bespoke solution is high, and the ability to discriminate between technology options challenging.”

Like any new technology, it is understandable that the uptake of CEA may meet some scepticism. Upfront investment and economic feasibility are valid concerns. However, there is long-term potential for the diversification of produce, especially when there are government grants available to ease the financial burden of setting up a facility.

Indoor farming is already gaining interest from supermarkets, retailers, pharmaceutical companies and investors. But more importantly, it may be the change we need to help overcome the food supply challenges on the horizon.

Farming for the future

Today’s global population stands at 7.8 billion, and by 2050, it is expected to reach 9.7 billion. The current prediction is that we will need to increase global food production byup to 70% to feed everyone. To make matters worse, we will need an extra 20% of land to achieve this using current farming practices.

Climate change is already affecting farmers across the globe with extreme weather patterns, including flooding and heatwaves, increasing in both frequency and intensity.

Furthermore, an increasing reliance on chemical herbicides and pesticides not only comes at greater costs to farmers, but also to the natural ecosystems and organic matter needed to maintain the quality of the soil.

CEA can help take positive steps towards a more sustainable, and profitable, future by reducing water consumption, the need for chemical intervention, logistics and land usage. In fact, farmers in Saudi Arabia are using CEA to grow fresh produce where it would be close to impossible in the country’s scorching outdoor temperatures and is ideally suited due to abundant sunlight for solar energy.

According to a report by the Boston Consulting Group (BCG), about one-third of the food produced globally is wasted, with much of that loss occurring along the global supply chain. Overall, that translates to 1.6 billion tons of food, worth about $1.2 trillion.

CEA allows for locally grown quick-to-market produce that can be bought and consumed where it is produced, with the traceability and integrity that food supply chains demand.

Rather than having their produce shipped across the world, farmers can use CEA to grow a wider variety of produce locally. This benefits everyone involved in the supply chain – right through to the consumer. As well as a better choice of products, CEA makes it possible to deliver food of consistent quality and quantity. There is also no need to add preservatives or wax coatings to keep fresh produce consumer-ready.

From an environmental perspective, the WorldWatch Institute found that the conventional food distribution system uses 4 to 17 times more CO2 than the local and regional systems.

What is the opportunity for regional farmers?

Many of the environmental and industrial changes mentioned above are already impacting farmers and exacerbating food security concerns. Time is of the essence to implement new practices that will help overcome them.

CEA has been a hot topic for the last few years, and it is a fast-growing sector: the Global Vertical Farming Market was valued at USD 3.12 Billion in 2019 and is projected to reach USD 16.77 Billion by 2027.

However, to achieve widespread adoption, it is important to show how CEA methods can benefit food producers today, as well as in the future.

What are the tangible benefits for regional farmers, right now?

Maximise growth 365 days per year

Nature is unpredictable, but with consistent optimum conditions, you can guarantee growth rate and the quality of produce.

Control growth

Synchronise ideal lighting spectrums, nutrient intake and transpiration with a crop’s various growth stages for optimum yield and quality.

Rely less on manual labour

Crop management can be automated or controlled by one person using digital applications.

Reduced reliance on chemicals

By removing crops from environments with pests and weeds, there is a reduced need for expensive and harmful chemicals to keep them safe. UV lights can also be used to control contamination.

Less water usage

General watering used in traditional farming methods to irrigate plants results in a greater water requirement than what is needed for a CEA facility.

Better use of facilities

Without relying on an expanse of fields, CEA allows more growth per acre than traditional farming. You can even convert barns and existing buildings into CEA facilities.

Take full advantage of government schemes

In the UK and Europe, many farming decisions relating to crops are based on what government subsidies are available at the time. In a move to encourage more environmentally conscious land management, there are a number of grants available for CEA.

Is CEA really feasible?

To make the investment more attainable, a small CEA facility can be considered farming equipment. This means you can approach the investment in the same way you would towards new machinery that increases your output – like a combine harvester for example.

With the right expertise, farmers can start out with a small-scale facility to test the ROI while minimising up-front investment.

“By buying components of a CEA farm, rather than full solutions, it is possible to improve existing horticultural operations, or start new farms, on a more simple and cost-effective basis,” states Dr. Stiles.

“This allows growers to experiment and develop systems which are optimised for their crop, circumstance and goals, without the significant barriers to entry. In many ways, this is an essential development for the CEA industry, as it could be argued the existing sector has been developing from the top-down rather than the bottom-up.”

“Many early adopters aimed to perfect large-scale factory-style systems from the outset, which was necessary due to the prohibitive cost of the technology. But this bypassed a lot of learning required to perfect systems such as these, which is partly why so many systems to date have failed.”

Introducing herbs, flowers, leafy produce and vegetables that do not grow too high or too deep in the soil, you can stack layers of plants in one building. And you don’t always have to invest in specialist construction – you may be able to repurpose barns and other empty spaces to house vertically or horizontally stacked layers of produce.

In fact, controlled growing environments have been housed inside shipping containers, garages, underground tunnels and even abandoned mine shafts. This paints a much more realistic picture than the behemoth skyscrapers featured in many aspirational articles about CEA. However, from both a construction and agricultural engineering perspective, CEA should always be optimised for the needs of specific production requirements.

Every step of the agricultural supply chain is already recognising the benefits of CEA. As noted earlier, starting small-scale allows you to test the potential for diversifying your produce on-site and be better prepared when CEA becomes more normalised in the future. Here are the basic principles to consider before getting started:

Humidity regulation

Dehumidifiers allow you to actively control the nutrient intake of plants by regulating the amount of water in the atmosphere for optimum transpiration.

Temperature control

As well as affecting the relative humidity levels inside a facility, heating and ventilation units are needed to maintain consistent conditions during warmer or colder months and to offset heat created by lighting.

Growing lights

LED growing lights are used to provide plants with all the nutrients they would naturally get from the sun. This fully-controlled lighting can be used to change the way plants grow, when they flower and how they taste by varying the light spectrum used at different growth stages.

Hydroponics

Unlike traditional irrigation, hydroponics distributes a nutrient-rich solution directly to the roots of plants.

Aquaponics

An alternative to hydroponics, aquaponics puts more oxygen in the root zone to help plants perform better. The plants receive their nutrients from a mist containing nutrients and water.

Successful CEA relies on using the configurations above to optimise climate, light and space:

“At the heart of every CEA system must be an understanding of the requirements of the plants you are aiming to cultivate,” explains Dr. Stiles. “If you understand what they need, what environmental conditions are most favourable for their growth, then these conditions can be recreated within a controlled environment.”

“In addition to this, and perhaps more intriguingly, an understanding of the potential of a plant is also advantageous. It is entirely possible to alter how plants grow, or the phytochemicals they produce, by changing environmental conditions. In this manner, there are opportunities to develop novel food or pharmaceutical products utilising this technology, which may offer enormous opportunities for growers.”

Start innovating with Dantherm

We believe on-site research, strong client relationships and a network of expertise is key to getting the best from any emerging trend or technology. This approach is based on our years of experience in the agricultural industry; specifically in providing climate control solutions for a range of applications including:

- Specialised growing

- Artisan food products

- Bulk storage

- Cold stores and freezers

- Food and drink production

- Livestock welfare

- Confectionery

- Agricultural equipment protection

With our extensive product range and expertise in agricultural applications, Dantherm has the specific industry knowledge to help enhance your current farming practices and take advantage of the opportunities presented by CEA.

To learn more about what CEA could mean for your facility, or for more information about our agriculture climate control solutions, don’t hesitate to get in touch with our team using the form below.

Related products

Featured insights

How to tackle moisture problems when storing bulk materials

The key to consistent cannabis growth is a well-specified dehumidification system

Why your stable needs a dehumidifier-powered drying room

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.