The reason behind ice build-up in freezers and cold stores. And what you can do about it.

- Home

- Insights

- Humidity control and drying insights

- The reason behind ice build-up in freezers and cold stores. And what you can do about it.

In this article, you’ll discover how to prevent the build-up of ice and avoid wasted produce, damaged packaging, hazardous working conditions and the time consuming process of regular de-icing.

Regulating humidity can save you a whole host of problems

The average temperature for cold food and beverage storage is usually between +3 and +5°C, dropping to around -25°C in freezer rooms. While humidity can cause problems in any facility handling food produce, especially in cold conditions, excess moisture in the atmosphere means unwanted condensation or ice build-up.

Relative humidity (RH) tells us how much water vapor is in the air, compared to how much it could hold at that temperature. Because warm air can hold more moisture than cold air, an environment’s relative humidity percentage is not a direct measure of the amount of water vapour present. For example, there will be more moisture in the air at 50% RH when the temperature is 25°C than there would be at 10°C.

Sudden changes in temperature will alter RH levels dramatically. When the air rapidly cools, RH levels can reach 100%, or dew point, causing the water vapour to condense. In sub-zero conditions, these water droplets freeze instantly.

Moisture-laden air can enter a busy freezer room or cold storage facility in a number of ways, including:

Building access

Humid air will find its way through building entrances that are left open too long, or automatic doors that close too slowly.

Sealing

Windows and other openings in a facility can let in humid air from outside or from other parts of the building.

Produce

Food products stored in a facility can often release moisture into the atmosphere.

Staff

People and vehicles in operation inside the facility can both increase humidity levels.

Why is ice build-up a problem?

In short, ice build-up will cost you time and money. Some of the most common symptoms are:

Damaged packaging

When ice begins to thaw, it will disintegrate cardboard packaging and cause labels to become illegible.

Low quality or wasted produce

When ice crystals form on food, flavours and aromas will be compromised and it can be left completely tasteless.

Productivity

De-icing a storage facility is a time consuming job. Having to do this regularly will reduce productivity due to the freezer being taken out of operation.

Slip hazards

As it spreads throughout a facility, ice and frost build-up will turn your storage room floor into a dangerously slippery surface for staff lifting heavy goods or operating forklifts. A build up of ice can also form on surfaces and ceilings which cause an additional hazard of breaking off and falling. You can also get slippery surfaces and low level fog forming outside of the freezer room door.

Equipment failure

Vents and evaporators are especially susceptible to malfunction and lower efficiency caused by ice build-up in mechanisms.

What’s the best solution for your facility?

The best solution is to minimise unwanted moisture entering the freezer and cold store. This can be achieved using desiccant dehumidification around entrance doors and any other areas of moisture infiltration.

To physically remove unwanted moisture from the atmosphere, a desiccant dehumidifier can be used. The desiccant rotor within the unit contains a network structure impregnated with silica gel which absorbs the moisture before the air is returned back into the space.

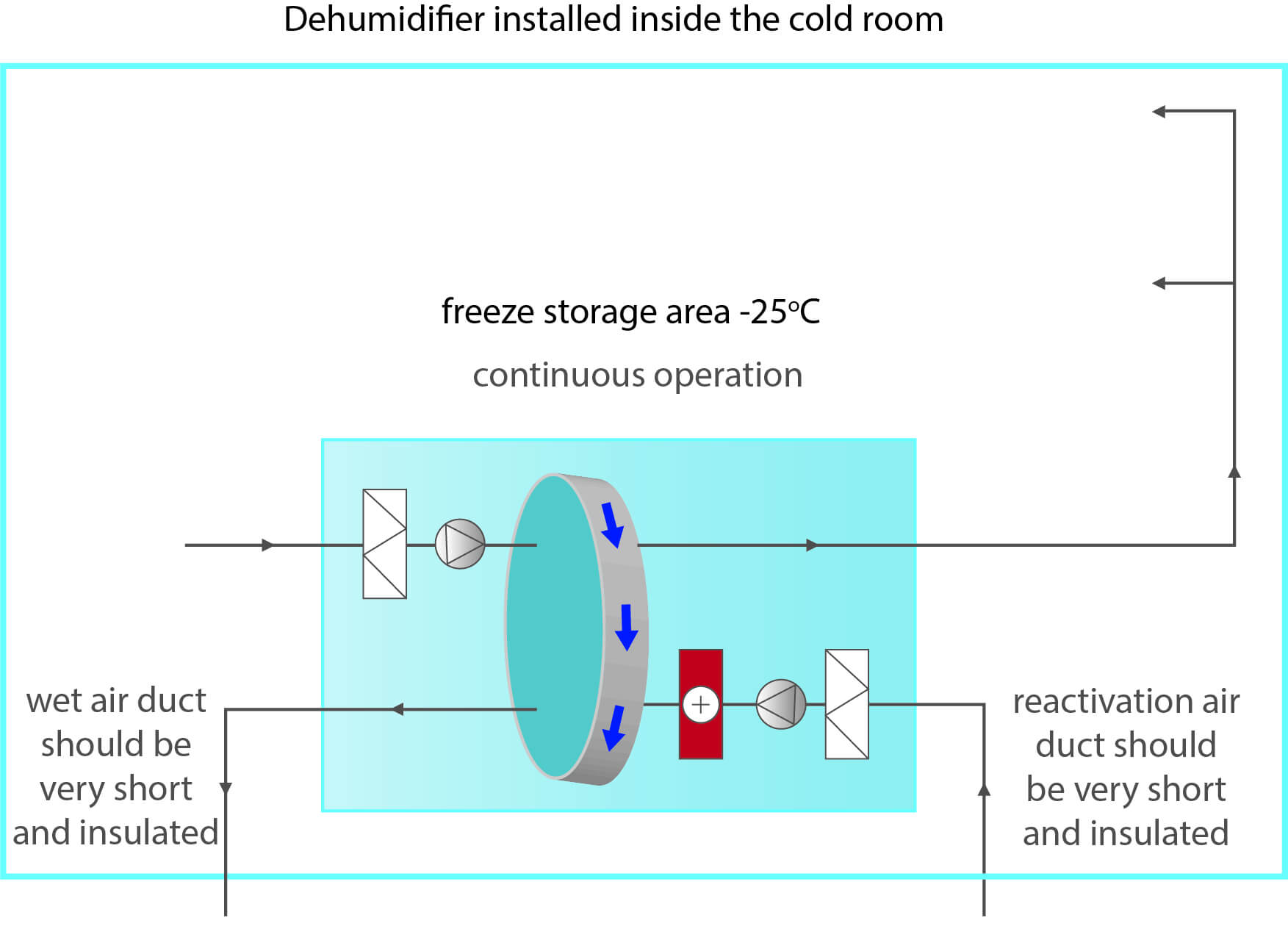

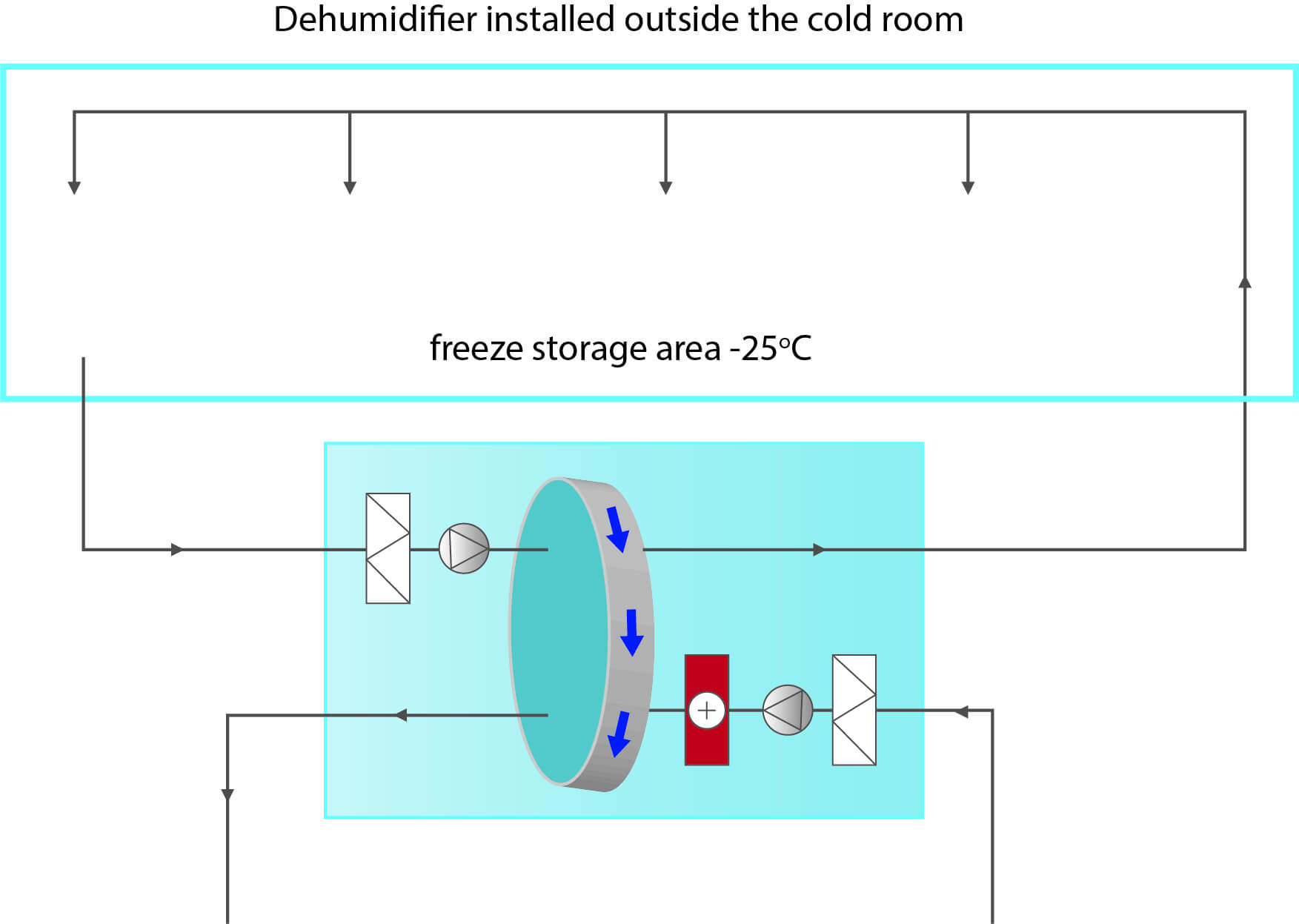

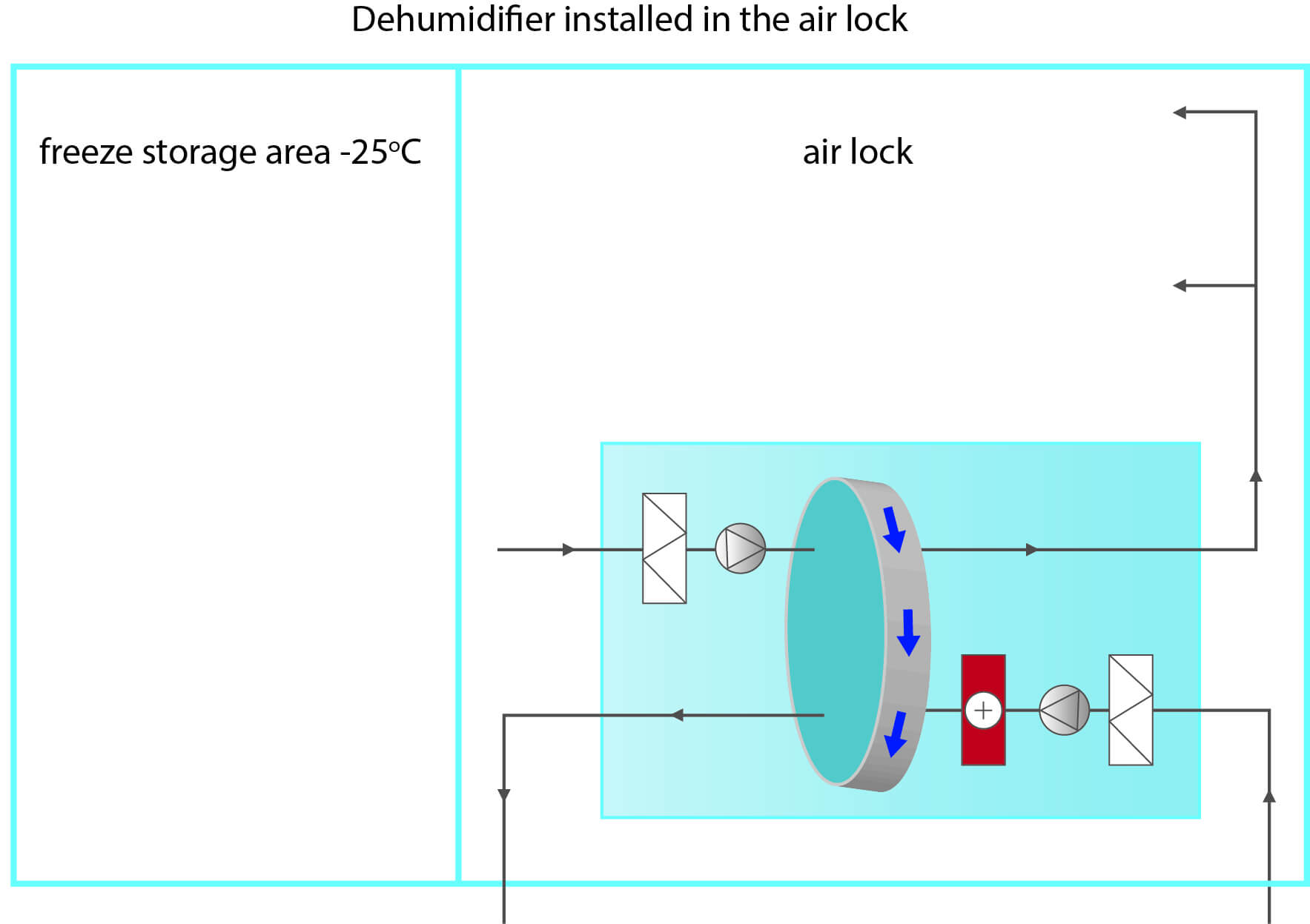

Dantherm Group can offer dehumidifiers suitable for installation, inside the freezer, outside the freezer or for dehumidifying a freezer air lock. As shown in the diagrams below:

Dehumidification solutions from Dantherm can be optimised for your setting and installed with minimal disruption to your process. To find out more about protecting your product and preventing the cost that comes with constant ice build-up, don’t hesitate to get in touch with our team.

Related products

Featured insights

Explore the benefits that can be unlocked by installing dehumidifiers outside of a cold store or freezer room.

Important reasons to implement an effective climate control system in your facility

How to optimise humidity during food production

Need help with choosing the right solution? Our team of over 100 climate control experts can assist.

You can also reach out or join the discussion on our Social Media. Check out our LinkedIn page.