Master BCM 311 – evaporative coolers

High efficiency cooling solutions for large industrial facilities. Master air coolers stand out for their low consumption and great efficiency, allowing air cooling of large spaces with a minimum operating cost.

Master BCM – evaporative cooler

|

Master industrial evaporative coolers

|

Master BCM top exit

|

Master BCM side exit

|

Master BCM installation example

|

Master BCM coolers installed on the roof

|

BCM coolers installed on the roof

|

Master BCM air flow

|

Master BCM coolers installed in a cow shed

|

Key features

-

Powerful cooling method available in 19,000m3/h, 31,000m3/h, 50,000m3/h

-

Control temperature and humidity

-

Low running costs

-

Easy to maintain

-

Evaporative filter pads, blocking dirt

-

Dust filter, blocking dust

-

UV lamp, disinfecting the water

-

Low energy consumption, 10% compared to traditional AC

-

Fresh, cool and healthy air to guarantee cool and clean environment

-

Full technical and commercial support available for dimensioning and project support

Benefits of evaporative cooling

-

Clean air that reduces the risk of bacteria and virus

-

No chemicals or refrigerants

-

Low energy consumption

-

Virtually maintenance-free equipment

How does it work

The outdoor hot air is moistened and cooled as it passes through water-soaked filters, then driven indoors at up to 12°C lower temperature. Thus, a constant flow of fresh and natural air is projected, which is introduced clean into the room, eliminating at the same time bad odours, germs and dust. This promotes the constant renewal of air that doesn’t recirculate, generating a healthy environment.

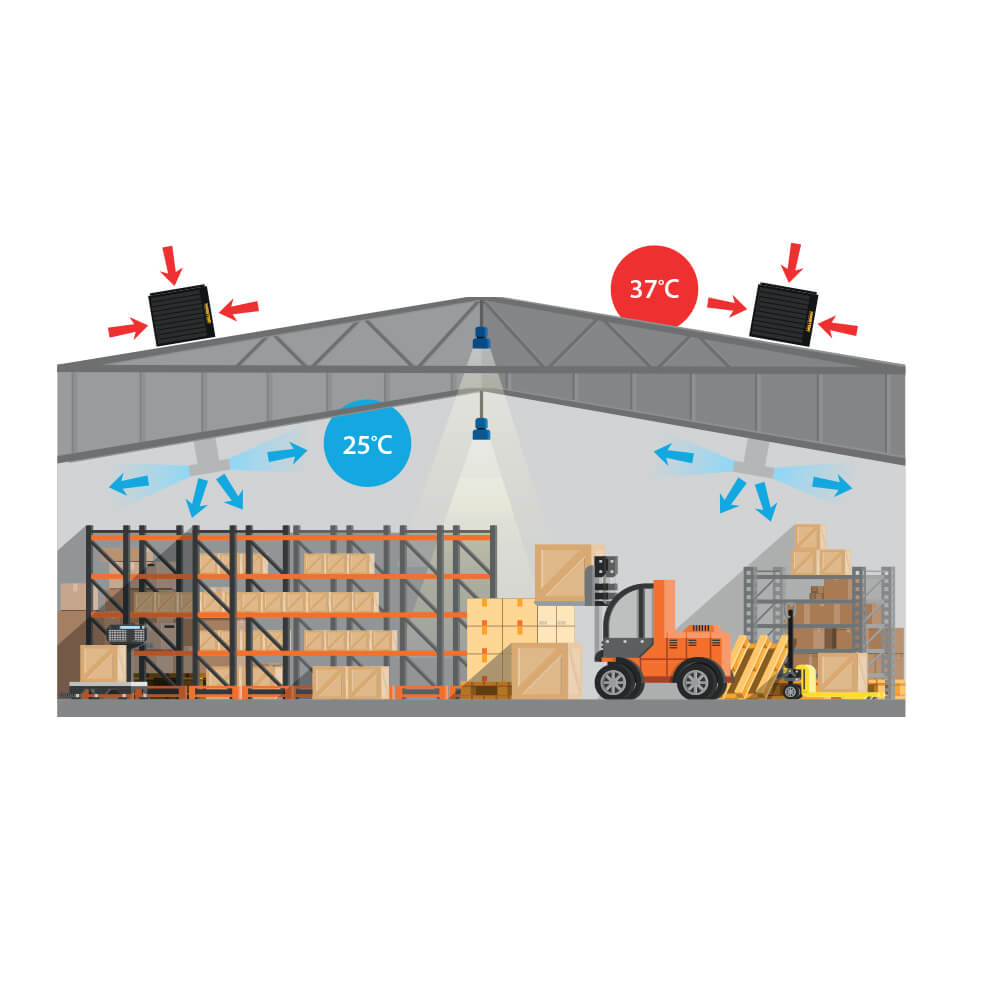

Installation example

Why Master?

Master evaporative systems adapt to our climate and are an excellent alternative to condition large spaces with low energy costs.

The installation is simple, since it’s sufficient with the positioning of the evaporative equipment on the roof or facade and connect it to a water supply and single-phase electric current. Thanks to its lightness, it doesn’t require cranes or large supporting structures for the installation and commissioning.

Self-management water cleaning system

Thanks to its electronic structure and components (electrovalve, drain valve and level sensors), Master equipment has an automated system for cleaning, emptying and filling water tank.

Pre-cool

The evaporative cooler enters in pre-cooling mode for one minute, just before the engine starts to operate, thus ensuring the cooling from the first moment.

Auto mode

With the previous adjustment of the required values of temperature and humidity, this mode allows to operate the equipment autonomously and efficiently by regulating its air flow rate, as well as water levels according to the values (Tº and %RH).

Auto clean

This function allows to set a period of time (hrs.) for the automation of units cleaning. Programmable period of time from 0 to 72hrs. The water drain valve opens allowing its exit and in this way the corresponding cleaning. After one minute the inlet solenoid valve opens, giving rise to a new water inlet in the tank. This self-cleaning mode is adjusted according to the measures and recommendations for prevention and control of Legionellosis.

Product specifications

| Specifications | Units | BCM 311 |

|---|---|---|

| Cooling pad - total surface |

dm³

|

306

|

| Cooling pad size - 1 pc. |

cm

|

87 x 88 x 10

|

| Air flow |

m³/h

|

31,000

|

| Fan type |

|

Axial

|

| Fan speed |

|

12

|

| Power consumption |

kW

|

3

|

| Power supply |

V/Hz

|

380/3ph/50-60

|

| Air exit |

mm

|

Down or top or side

|

| Tank capacity |

l

|

50

|

| Water consumption |

l/h

|

30-50

|

| Remote control integration |

SM 4.0

|

Yes

|

| Product size (l x w x h) |

mm

|

1280 x 1280 x 1170

|

| Weight |

kg

|

86

|